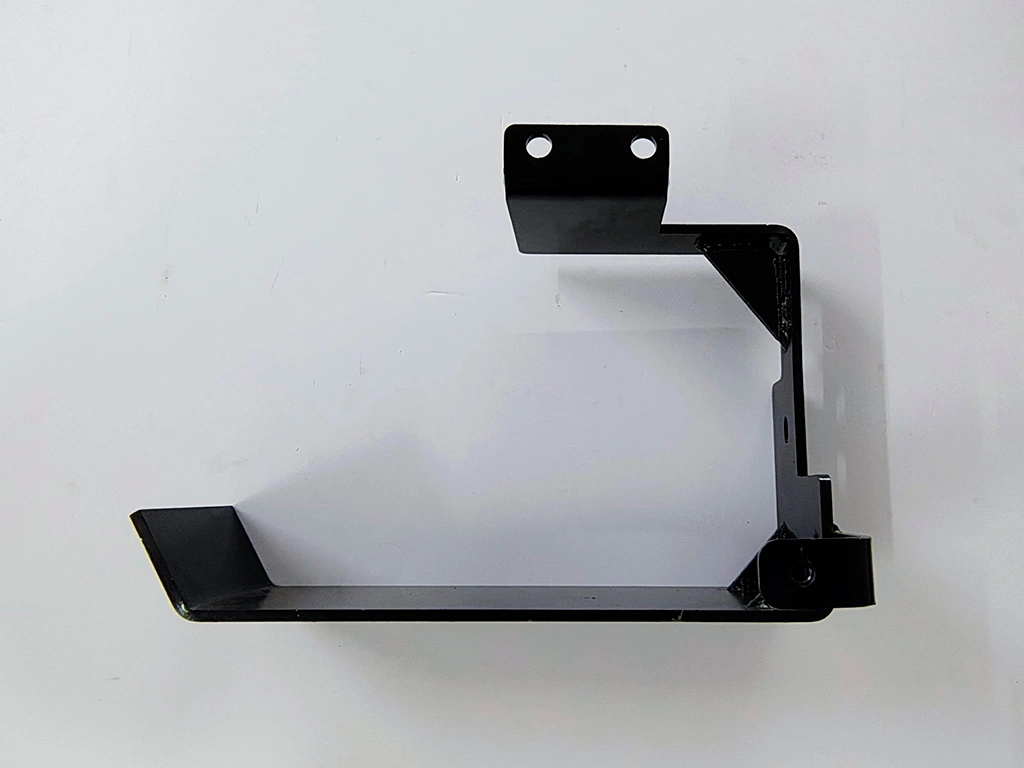

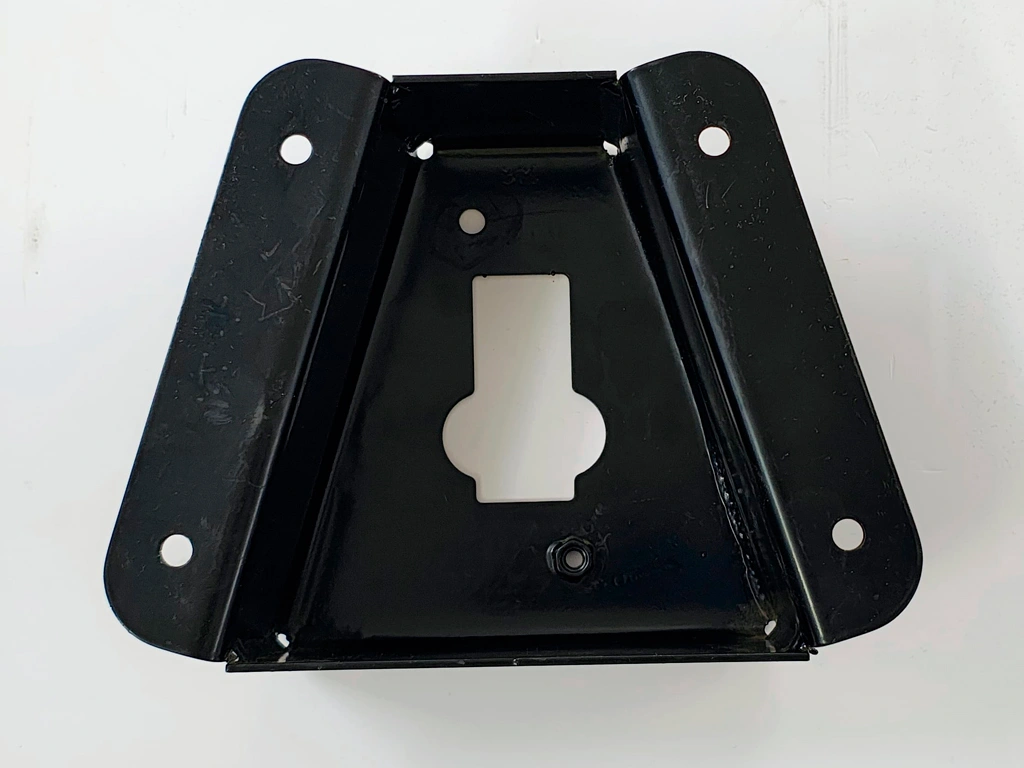

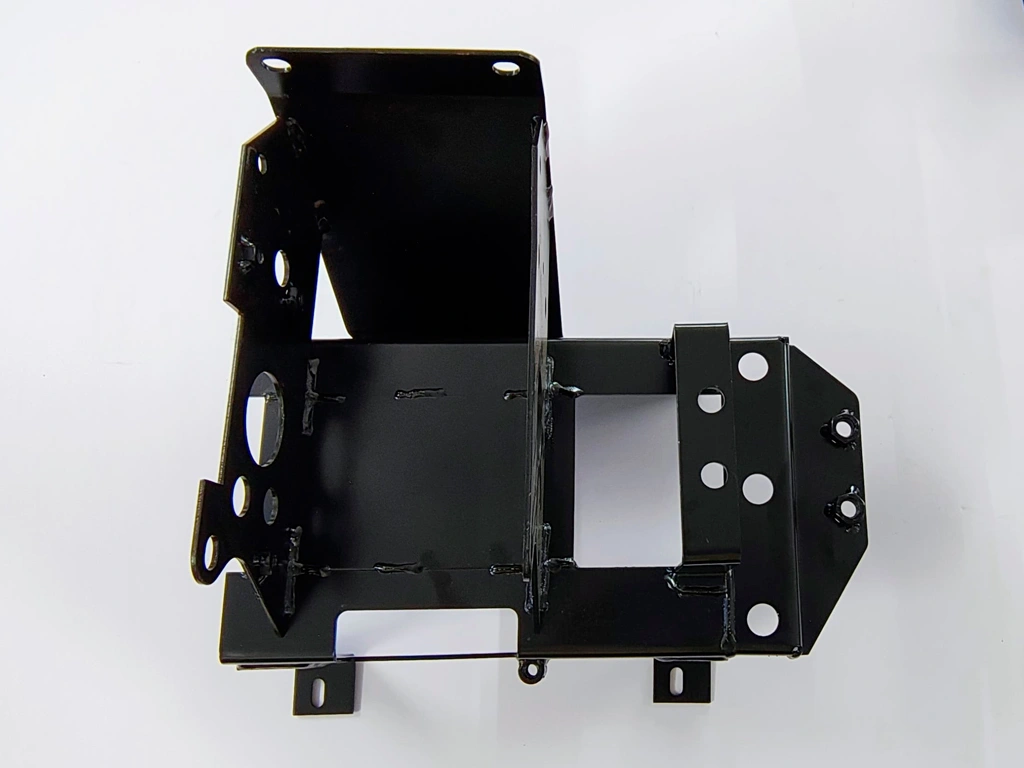

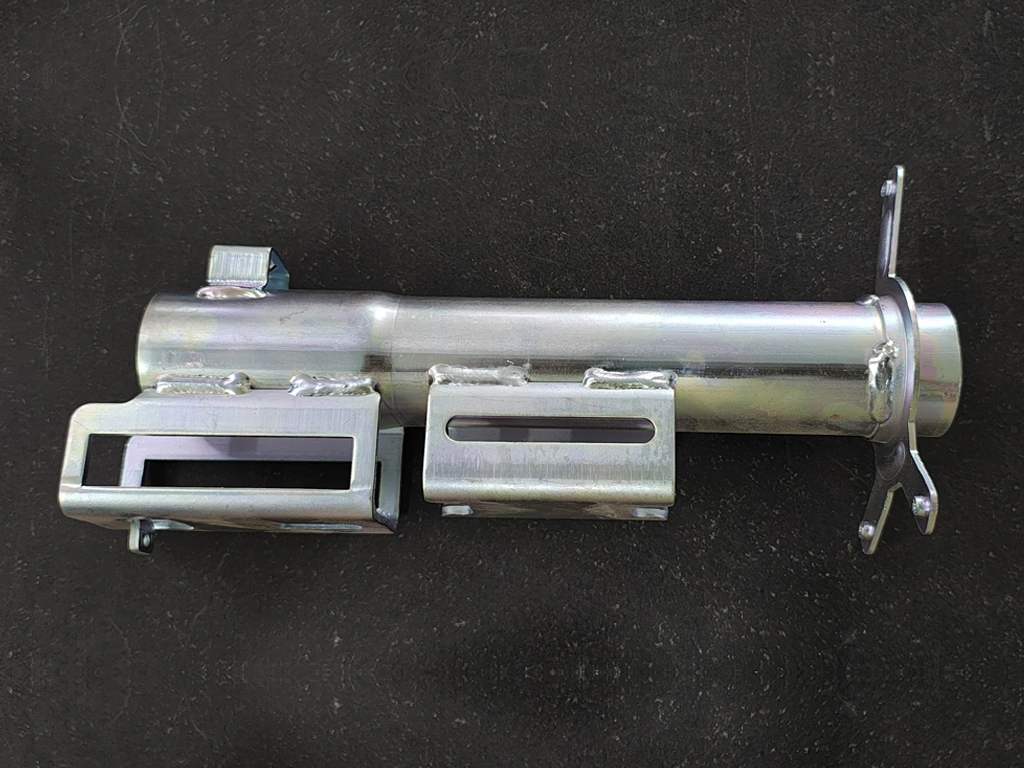

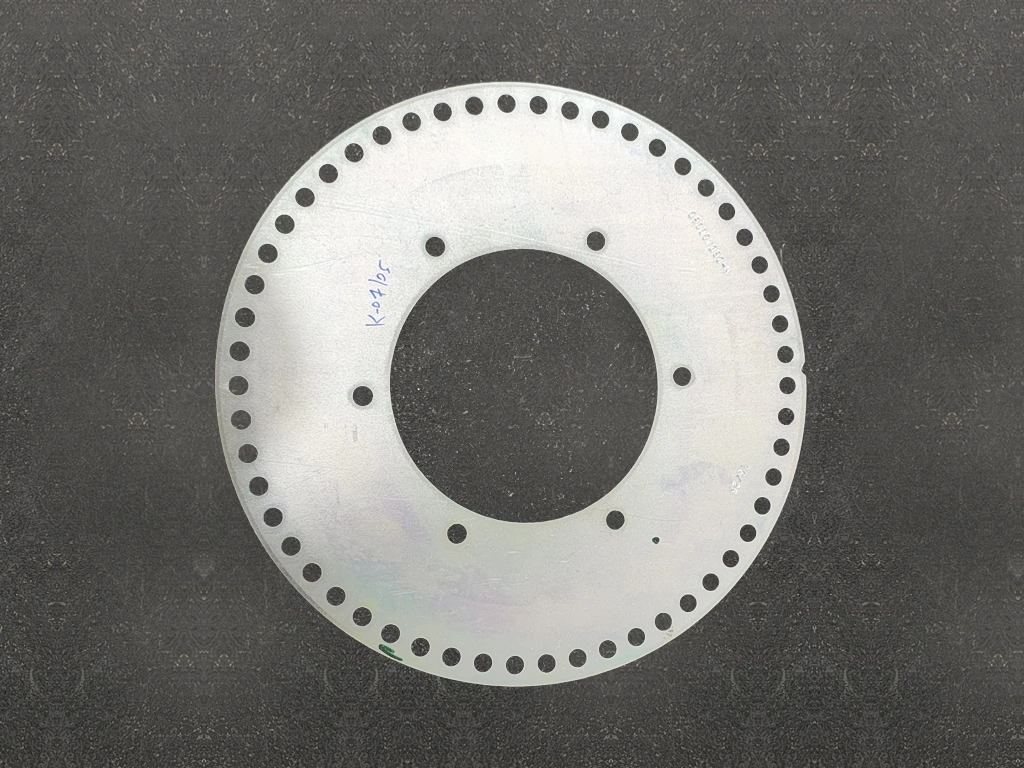

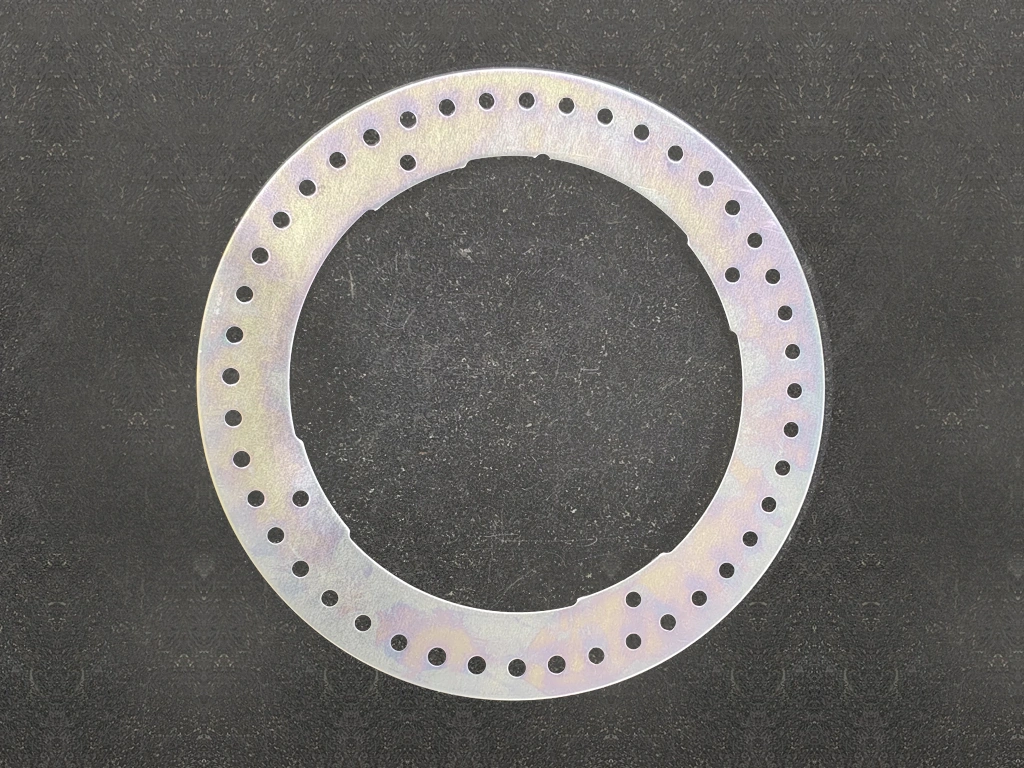

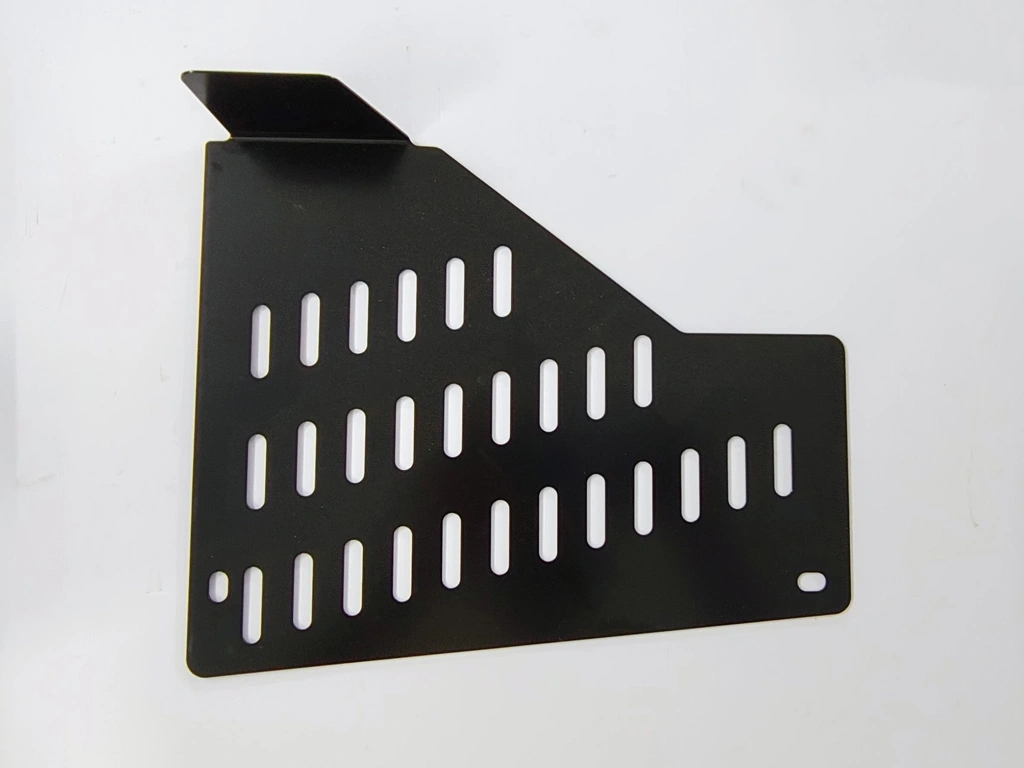

Auto Components

SSMI produces precision-engineered auto components and sub-assemblies of over 500+ products. We provide precision-engineered auto components and sub-assemblies to global automotive OEMs and renowned Tier 1 customers. Our components are meticulously crafted to meet stringent customer quality standards, ensuring optimal performance and durability in every part delivered.

Technological Investment: Our division is heavily invested in advanced technology machinery to ensure compliance with quality and customer requirements. Our state-of-the-art equipment includes:

Stamping Press Machines: 24 units with specifications ranging from 20T to 250T.

Power Press Machines: 18 units ranging from 20T to 200T.

Pneumatic Press Machines: 4 units ranging from 40T to 250T.

Laser Cutting Machine: Top brand laser cutting machine capable of cutting various metals with position accuracy of ±0.03 mm and repeatability accuracy of ±0.02 mm. Specifications include a 6KW capacity, double movable cutting bed (3000 x 1500 mm), and maximum metal cut thicknesses of 25 mm for mild steel, 18mm for stainless steel, 10 mm for aluminium, 8 mm for brass.

Press Brake Machine: Flexible bending capabilities with specifications of 200 MT, 3000 mm length x 220 mm bed size.

In-House Tool Room: Our in-house tool room provides a significant advantage by offering greater control over tooling and faster response times for adjustments or customizations.

Hydraulic Press Machines: 2 units with capacities of 100T to 200T.